Powder Coating is an advanced method of applying a decorative and protective finish to virtually any type of metal that can be used both by industry and consumers. The powder used in the process is a mixture of finely ground particles of pigment and resin, which is electrostatically sprayed onto the surface to be coated. The charged powder particles adhere to the electrically grounded surfaces until the powder is heated and fused into a smooth coating in the curing oven. The result is a uniform, durable, high quality and attractive finish. Powder coating is the fastest growing finishing technology in America, representing over 10% of all industrial finishing applications.

It’s more durable

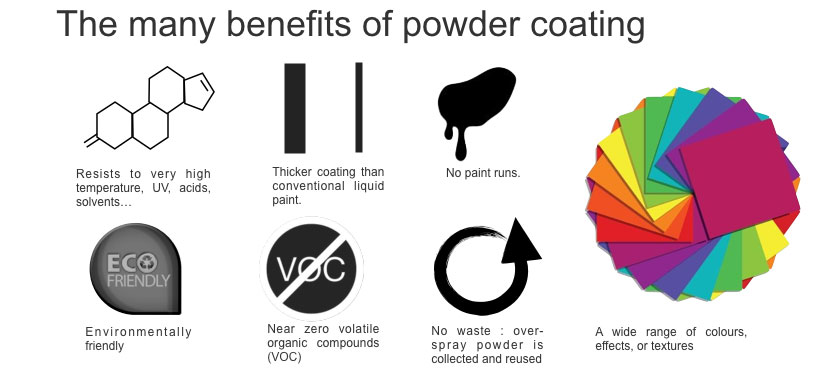

Powder Coating gives consumers, businesses, and industries one of the most economical, longest lasting, and most color-durable quality finishes available on virtually any type of metal. Powder coated surfaces are more resistant to chipping, scratching, fading, and wearing than other finishes. Color selection is virtually unlimited with flat, satin, gloss, high gloss, metallic, candies, clear, iridescent, fluorescent, wrinkle, hammer tone, and glitter finishes available. Colors stay bright and vibrant longer. Texture selections range from smooth surfaces to wrinkled or matte finishes, and rough textures designed for hiding surface imperfections.

It protects the environment

Powder Coating is also highly protective of our environment. While liquid finishes contain solvents which have pollutants known as volatile organic compounds (VOC’s), powder coating contains no solvents and release negligible amounts, if any, VOC’s into the atmosphere. Therefore, there is no longer a need for finishers to buy and maintain costly pollution control equipment.

It saves money!

Elimination of VOC’s and the reduction of waste saves money and helps companies comply more easily and economically with the regulations of the U.S. Department of Environmental Protection Agency. In fact, one of the major elements in expanding the market for powder coating has been the implementation of stringent air pollution control legislation over the past thirty years.

Best for Automotive Industry

The automotive industry uses powder coating on wheels, bumpers, hubcaps, door handles, decorative trim and accent parts, truck beds, radiators, filters, and numerous engine parts. A clear powder topcoat has been developed to protect auto bodies. BMW and Volvo are using it on their new model cars, and GM, Ford, and Chrysler have formed a consortium to test this technique on their production lines.

Get up to $3000

Bad credit or no credit? No problem!

Snap doesn't offer traditional loans. Instead, we offer a consumer lease that allows you to finance the merchandise over 12 months of convenient payments. We also offer a 100-Day payment option, the best terms around. Need new tires for your car? Or need automotive repair? Don't let bad credit stand in your way. Snap is your partner for fast and easy lease-purchase financing. Please apply here https://nxt.to/qdNWBpA

Snap doesn't offer traditional loans. Instead, we offer a consumer lease that allows you to finance the merchandise over 12 months of convenient payments. We also offer a 100-Day payment option, the best terms around. Need new tires for your car? Or need automotive repair? Don't let bad credit stand in your way. Snap is your partner for fast and easy lease-purchase financing. Please apply here https://nxt.to/qdNWBpA

FINANCING : Snap! Finance

Snap! Finance has the following benefits:

- Get up to $3,000, NO CREDIT NEEDED!

- Easy electronic application with Instant approval.

- Only $39 down (cash, credit or debit).

- 100 day CASH payoff with no early buyout fees!

- Other discounted payment options available.

- No additional documents required (e.g. paystubs).

What you will need to apply:

- Social Security number or ITIN

- Be 18 years or older.

- Active checking account.

- At least $1000 in income per month.